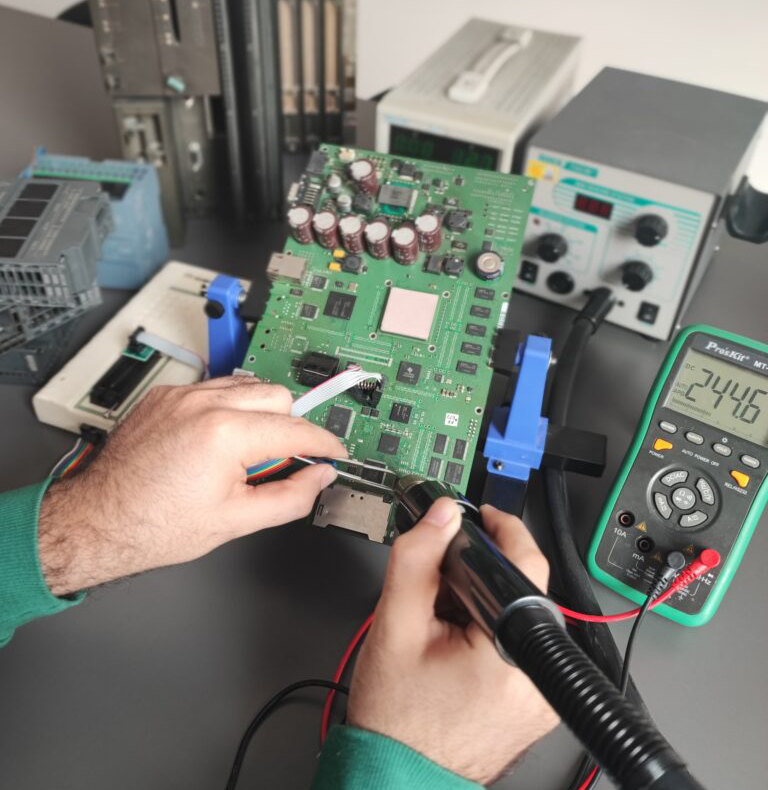

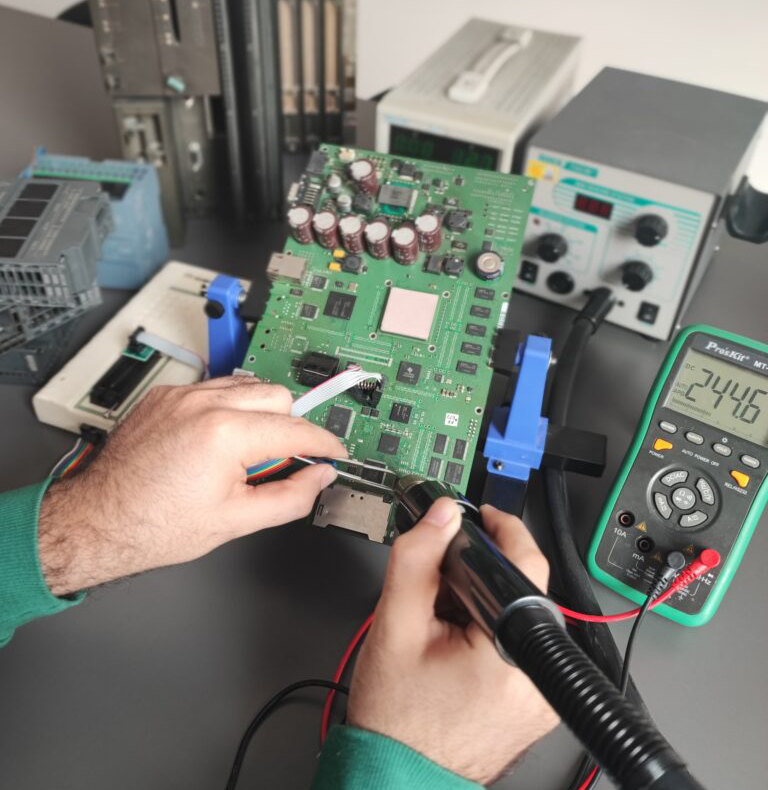

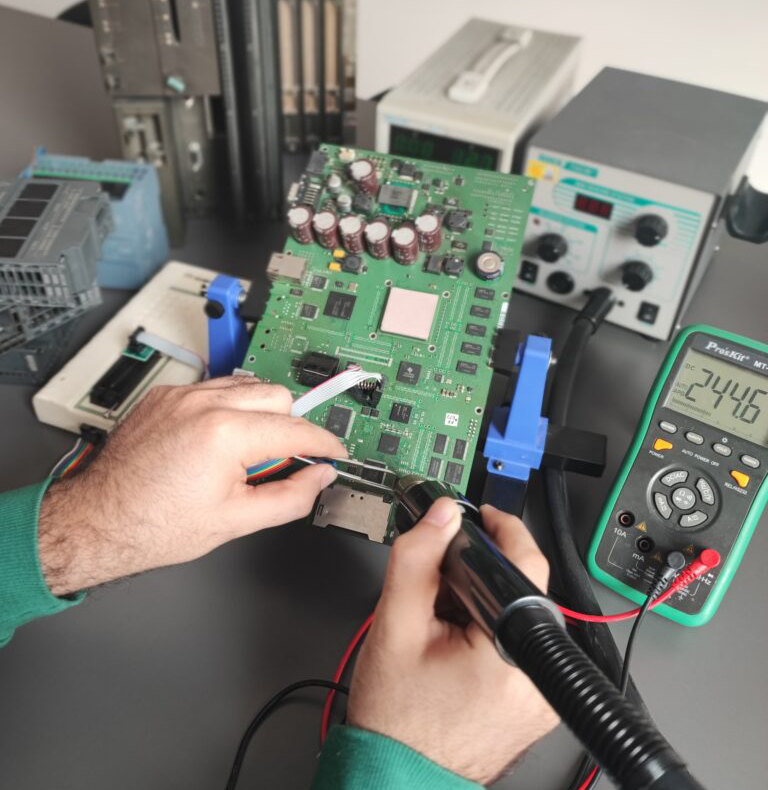

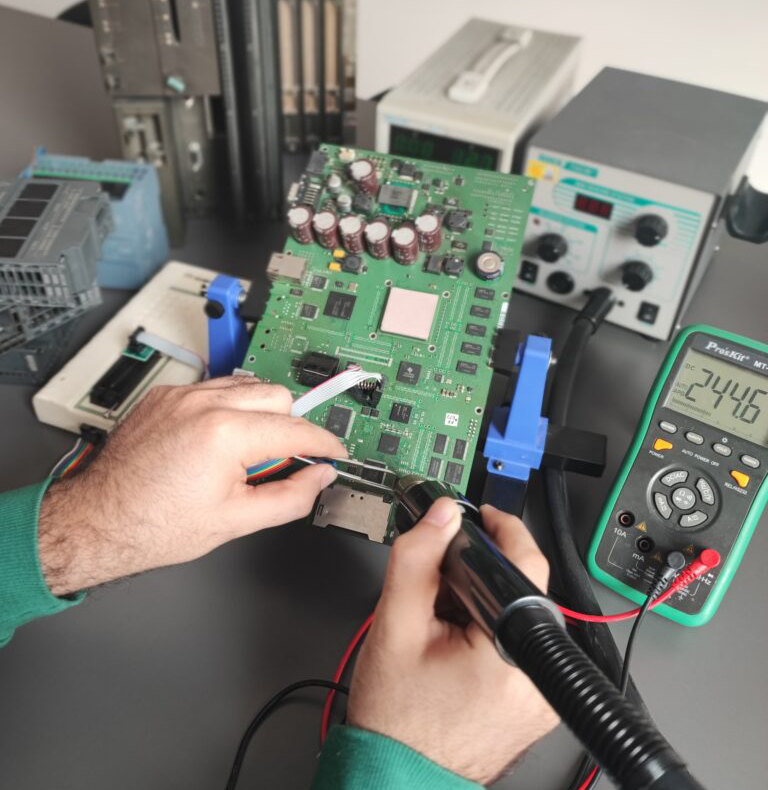

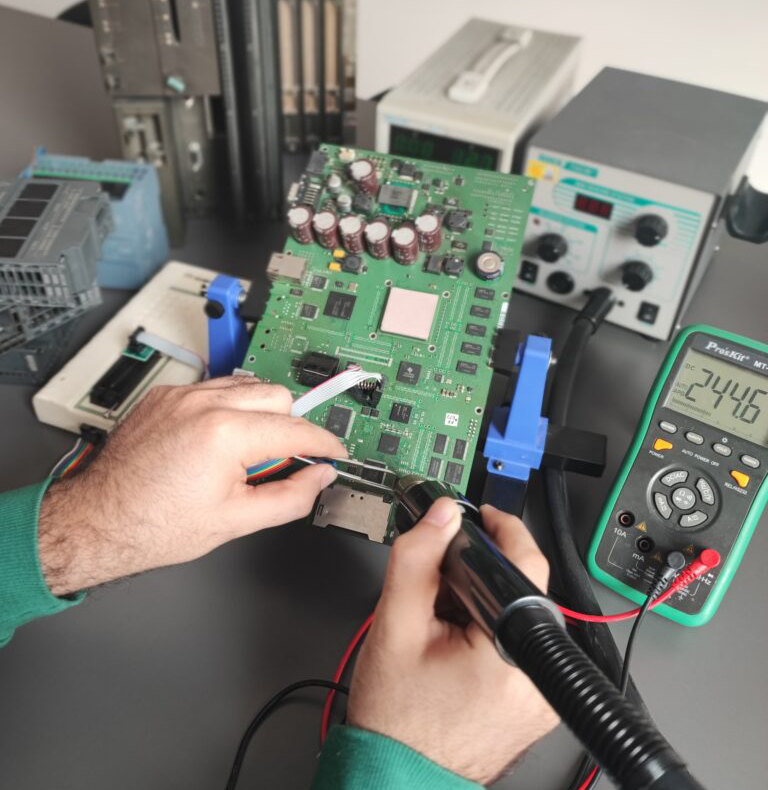

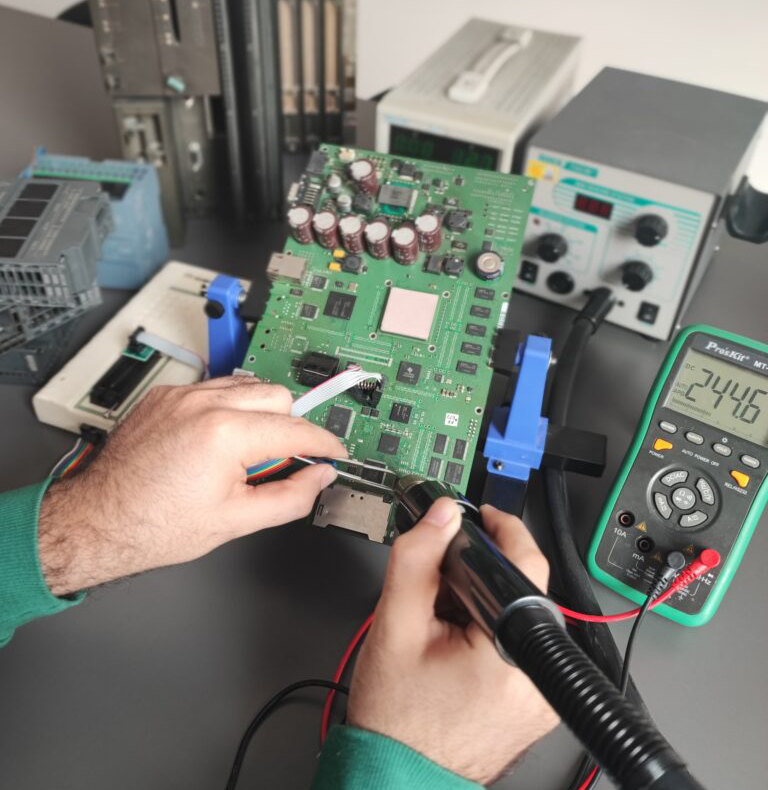

The after-sales service unit of Qeshm Voltage Company has been operating in the field of specialized repairs and troubleshooting of Siemens industrial automation equipment since 2004. Over the years, by utilizing the most advanced laboratory testing and control tools, as well as using original and high-quality spare parts, it has become known as a specialized center for repairing Siemens industrial automation equipment nationwide.

The services of this unit to its esteemed customers and employers are aimed at saving time and money and improving the quality level of production lines in various industries, including oil, gas, petrochemicals, steel, cement, automotive, pharmaceuticals, food industries, wood and paper, etc., and it has always prevented production from being stopped in difficult and emergency situations by providing assistance and troubleshooting the automation equipment of production lines and preventing possible costs incurred by purchasing equipment that has been removed from the Siemens production range or purchasing new devices. It hopes to provide the best and most effective services to its esteemed customers by taking advantage of its up-to-date knowledge and experience.

Description of the activities of the repair unit :

A brief list of activities carried out in the repair unit is presented below :

Testing and repairs of all types of Siemens HMI

Including: Touch screen replacement, LCD replacement – Panel PC, motherboard, Operation Panel, Touch Panel, Multi Panel repair

Testing and repairs of all types of Siemens PLCs

S7-200 – S7-300 – S7-400 – S7-1200 – S7-1500 – LOGO + related modules

Testing and repairs of all types of Siemens DRIVE

Micromaster -Master drive MC & VC – Simoreg – Simodrive 611 – Sinamics – Soft starter

Testing and repairs of various types of Siemens CNC controllers

802 C,D – 810 D,E – 840 D,C,E – 808 – 828 DSL and related modules

Testing and repairs of all types of Siemens power supplies and protection relays

Including: Touch screen replacement, LCD replacement – Panel PC, motherboard, Operation Panel, Touch Panel, Multi Panel repair

Testing and repairs of precision instrumentation equipment

Testing and repairs of various robot boards and robotic system’s production lines

The after-sales service unit of Qeshm Voltage Company has been operating in the field of specialized repairs and troubleshooting of Siemens industrial automation equipment since 2004. Over the years, by utilizing the most advanced laboratory testing and control tools, as well as using original and high-quality spare parts, it has become known as a specialized center for repairing Siemens industrial automation equipment nationwide.

The services of this unit to its esteemed customers and employers are aimed at saving time and money and improving the quality level of production lines in various industries, including oil, gas, petrochemicals, steel, cement, automotive, pharmaceuticals, food industries, wood and paper, etc., and it has always prevented production from being stopped in difficult and emergency situations by providing assistance and troubleshooting the automation equipment of production lines and preventing possible costs incurred by purchasing equipment that has been removed from the Siemens production range or purchasing new devices. It hopes to provide the best and most effective services to its esteemed customers by taking advantage of its up-to-date knowledge and experience.

Description of the activities of the repair unit :

A brief list of activities carried out in the repair unit is presented below :

Testing and repairs of all types of Siemens HMI

Including: Touch screen replacement, LCD replacement – Panel PC, motherboard, Operation Panel, Touch Panel, Multi Panel repair

Testing and repairs of all types of Siemens PLCs

S7-200 – S7-300 – S7-400 – S7-1200 – S7-1500 – LOGO + related modules

Testing and repairs of all types of Siemens DRIVE

Micromaster -Master drive MC & VC – Simoreg – Simodrive 611 – Sinamics – Soft starter

Testing and repairs of various types of Siemens CNC controllers

802 C,D – 810 D,E – 840 D,C,E – 808 – 828 DSL and related modules

Testing and repairs of all types of Siemens power supplies and protection relays

Including: Touch screen replacement, LCD replacement – Panel PC, motherboard, Operation Panel, Touch Panel, Multi Panel repair

Testing and repairs of precision instrumentation equipment

Testing and repairs of various robot boards and robotic system’s production lines

Note : Dear customer, in order to prevent misuse of the name of Qeshm Voltage Company and damage to production line systems by profit-seeking individuals, this company hereby announces that it does not have any representatives outside its group. (And only requests that are submitted directly to the group and answered through the group are valid.)

The after-sales service department of Qeshm Voltage Company has been active in the field of repairs and troubleshooting of Siemens and non-Siemens industrial equipment since 2004. A brief list of the activities carried out in the Repair and Troubleshooting Unit is presented below for your service:

- Motor

- Instrument

- Power Supply

- Drive: Micro Master, Master Drive VC, MC, Simoreg

- PLC: S7-400, S7-300, S7-200, LOGO, S5 + Relevant modules

- CNC: CNC 802C, D, CNC 810D, E, CNC 840D, C, E, CNC 808

- Low and Medium Voltage, Relay, Power, Soft Starter, Simotion

- Panel: Panel PC, Operation Panel , Touch panel, Multi panel, PCU

Also, dispatching an expert to the client’s site for setup, troubleshooting, even with a password and backup of the existing system, and providing a solution to solve the problem. Therefore, please contact:

- Please call +982166733040, extension 150, or mobile +989391904085.

- Please call +989124379694 during non-business hours.

- If you want to contact us on Telegram, click here.

It should be noted that if the client needs to install and commission the repaired parts, this company also has the option of sending a technical expert to the client’s site; this can be done and followed up by the specialists of the company’s on-site service unit (troubleshooting). For more information about the unit, you can refer to the relevant section on this website.

The parts repaired by this company have been related to various industries, including the following :

- Gas

- Oil

- Cement

- Petrochemicals

- Automotive

- Steel

- Plastic

- Parts manufacturing

- Wood and Paper

- Tile and Ceramics

- Copper

- Textiles

- Aluminum

- Iron smelting

- Food

How the maintenance unit works

The way the repair unit works is that all customer parts are registered in the company’s comprehensive system after being received by the unit’s experts, and after receiving a description of the damage and problem of each part from the client, they are subjected to initial testing and examination by the technical experts related to that part. In the next step, each part, along with a complete report describing the reported damage, is delivered to one of the repairers related to that part for a complete evaluation. Based on the investigations carried out, as well as the type of damage and failure of the part and the amount of consumables required to repair each part, the cost of repairs for that part is calculated and notified to the client in the form of a proforma invoice. If the proforma invoice sent is approved by the client, the repairs of the part will begin. After completing all the repair steps, the part will be handed over to technical experts for final testing and confirmation of correct performance. If approved by the company’s experts, the client will be informed of this issue so that the settlement and release steps of the part can be carried out.

As one of its special services, the company’s repair unit includes all customer parts purchased from this company and can repair them free of charge for up to one year under warranty.