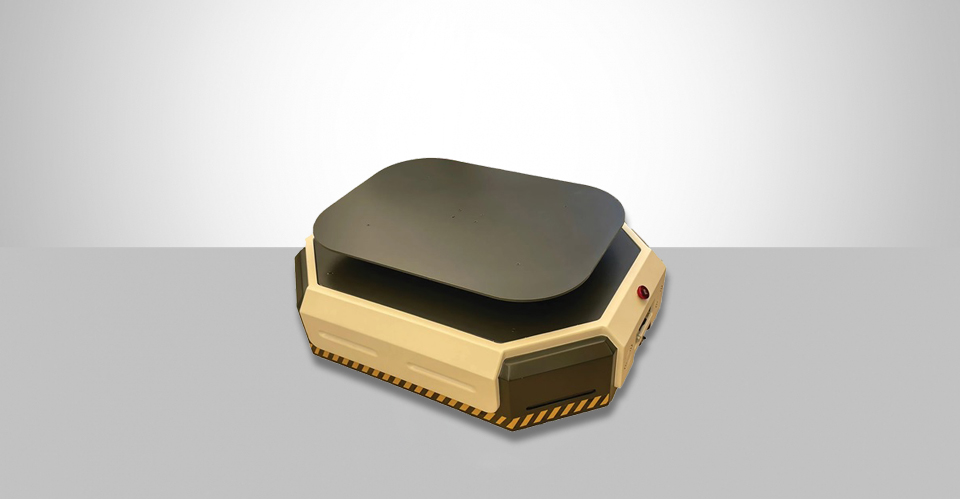

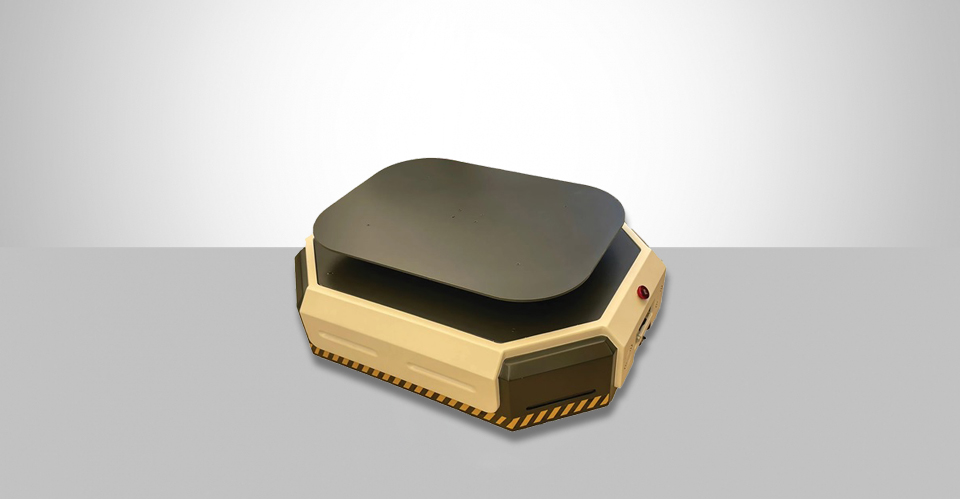

QVR-AGV warehouse robots are capable of carrying goods and can even select short, obstacle-free paths for transport from one location to another.

Additionally, they have the ability to move a larger number of items in less time. With their high efficiency and speed, they will be a significant help in warehousing practices. Although these robots are not designed in human form and have their own unique appearance, they are specialized and highly accurate in performing their tasks with a very low error rate.

QVR-AGV warehouse robots are capable of carrying goods and can even select short, obstacle-free paths for transport from one location to another.

Additionally, they have the ability to move a larger number of items in less time. With their high efficiency and speed, they will be a significant help in warehousing practices. Although these robots are not designed in human form and have their own unique appearance, they are specialized and highly accurate in performing their tasks with a very low error rate.

Advantages of warehouse robots

Such a system is designed to increase the productivity and efficiency of the warehouse and to reduce dependence on human resources and, naturally, reduce errors in maintaining and maintaining inventory and other services in this profession.

In manual warehouses, we typically see workers holding inventory lists, walking around the warehouse, selecting products, loading them onto trolleys, and then sending them to their destination. In a smart warehouse, however, orders are automatically received, the system then confirms the inventory, and a picking list is sent to the robots. The products are then ultimately handed over to employees for the next stages.

How QVR-AGV works

A warehouse robot based on technology is part of an advanced technological ecosystem where goods are received, identified, sorted, organized, and transported automatically. In the best-case scenario, all operations from the supplier to the customer are performed with automatically and minimal errors.

The operation of the QVR-AGV robot is as follows: the robot moves toward the target item on a shelf and stops at the closest possible location. In the next stage, the item is placed on the warehouse robot from the shelf by a human worker or another robot (such as a palletizer, industrial arm, Cartesian robot, etc.). The robot then moves the item toward the next destination, which could be another shelf in a different part of the warehouse or a location for delivery to the customer.

Product specifications

|

name

|

Code

|

body material

|

Engine type

|

Weight (kg)

|

Dimensions (cm)

|

Jack course length

|

|---|---|---|---|---|---|---|

|

Warehouse robot

|

QVR-AGV

|

Steel body with ABS cover

|

Encoder

|

45

|

107x71x23

|

15

|

Capabilities

- • Line following

- • Visual routing

- • Collision avoidance

- • New generation radar

- • Obstacle detection and rapid response to obstacles

- • User interface software

- • Load carrying up to 50 kg

- • Group collaboration capability

- • Intelligent planning system

- • Various programmed modes

Raw materials for machining include: steel sheets and profiles, aluminum belts, and raw materials for 3D printers.

- Encoder (two)

- Laser scanner (two)

- Bearings (six)

- Drive wheel (two)

- Idler wheel (four pieces)

- Jetson processor

- Timing belt (two pieces)

- Timing pulley (four pieces)

- Jack with stroke capacity up to 15 cm

- Durable steel body with ABS cover

- • Research and field studies in the mechanical section, type of mechanism used (mechanical)

- • Initial design based on information received (mechanical and electronics)

- • Final design (mechanical and electronics)

- • Cost estimate (mechanical and electronics)

- • Receiving approval of design documents from the employer (mechanical and electronics)

- • Preparing a list of parts for purchase (mechanical)

- • Finalization of manufacturing drawings for the mechanical and electrical sections

- • Procurement of machined parts based on manufacturing drawings (Mechanical)

- • Assembling the mechanical section

- • Assembling the electrical section

- • Programming (electronics)

- • Initial testing and commissioning and final testing (mechanical and electronics)

- • Installation and commissioning at the employer's site (mechanical and electronics)

- Mechanical: 60 working days after receipt of the down payment